Technology

Technology

Concrete FLoating Wind Foundations

DeepCWind specializes in the commercial design and implementation of concrete floating foundation technology developed aby the University of Maine.

UMaine has developed a 4-column semi-submersible and a cruciform barge technology called the “+”. Both have been demonstrated offshore and grid-connected with 3rd party review by clacification societies.

UMaine has been at the forefront of floating wind and deployed the first floating wind turbine in the US in 2013 and the 2nd in 2025.

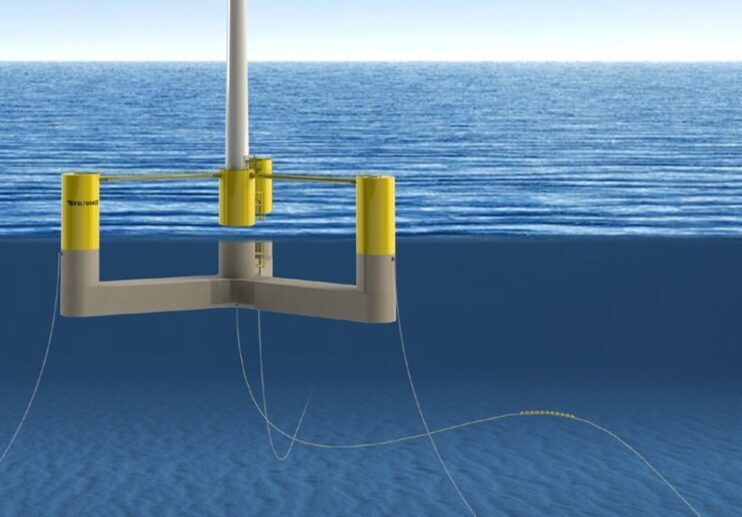

VolturnUs + Damped Concrete Cruciform Barge

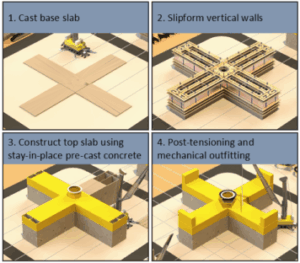

The “+” is a 2nd generation floating foundation developed through a $14M investment competition from the US Department of Energy An offshore demonstration in the North Atlantic is in progress.

The floating foundation design is inspired by concrete caisson technology and designed for serial slip forming concrete production. The foundation includes a passive damping technology to reduce its size by 20-30% while also mitigating barge motions to keep turbines within type certificate loading.

KEY FEATURES

- Low-cost serially produced concrete floating foundation: simple shape and small footprint

- High local content opportunities

- Patented passive damper technology

- Demonstration in progress

- 3rd party Approval in Principle received from Bureau Veritas and American Bureau of Shipping

VolturnUS Concrete Semi-submersible

The Volturnus Semi-submersible was demonstrated in 2013 and was the first grid-connected offshore wind turbine in North America. Semi-submersible technology has been well proven in the oil and gas sector and more recently in floating wind. The Volturnus semi represents a high optimized configuration for floating wind developed over the past decade through tank testing, engineering, and offshore deployment.

Key Features

- Concrete floating foundation with standardized sections compatible with mass concrete production methods

- Demonstration completed in 2013

- Multiple FEEDs with integrated load analyses completed with full-scale turbine OEMs

- 3rd party design approvals received

- Higher local content opportunities than steel foundations